- Home

- Stretch Wrap Film Gauge

Stretch Wrap Film Gauge

Knowing which stretch wrap film gauge your company requires is the first step. Our stretch wrap is available in a variety of gauges and thicknesses and is distributed by Toronto Stretch Wrap and Danshar Polybag and Resin Inc. to manufacturers, wholesales, and end-users. Available in various sizes and colors, guaranteed top quality stretch wrap is available for your business bundling needs at competitive rates. Our stretch film offers better load integrity and is high performance, which reduces costs per load and translates into cost savings for your business.

Toronto Stretch Wrap and Danshar Polybag and Resin Inc. offer a complete line of stretch film available in hand and machine formats. We strive to sell sustainably manufactured stretch film through a reduction of energy use and production of waste, as well as decreased carbon emissions. Providing environmentally sustainable options remains of utmost importance to us as it is to our consumers.

Stretch Wrap or Shrink Wrap?

Stretch wrap and shrink film are often confused for one another but possess entirely different characteristics. Stretch wrap is made from polyethylene resins while shrink wrap is manufactured from polyolefin films. Stretch wrap and shrink film vary in their applications, as well as their intended usages. Stretch wrap is generally used to wrap boxes tightly on a pallet load, while shrink wrap is loosely applied to individual products. Heat is then applied with a heating gun and will shrink to securely cover the product. While stretch wrap is commonly used throughout factories, warehouses, and distribution centres to wrap pallet loads for storage and shipments, shrink wrap is generally used to protect a single product from the elements, such as outdoor furniture, boats, and food products.

While heat is required to activate shrink wrap, stretch wrap requires no heat and can be wrapped manually or by machine. Unlike shrink wrap, which is loosely applied around your products and does not have a high stretchability rate, stretch wrap has an elastic recovery that allows items to always remain tightly held. For bundling cartons and other applications, sturdy pallet stretch wrap is the ideal choice and comes in various sizes and gauges to suit specific needs. Stretch wrap is the preferred choice for wrapping industrial products. Conversely, shrink wrap is rarely used to wrap pallets and is generally used to wrap retail and food products.

Each stretch wrap brand can vary in its break strength, tear resistance and clarity; the most common type of material used for stretch wrap is linear low-density polyethylene (LLDPE). Used for several functions and available in several stretch wrap film gauges, this product helps provide a unit load with a more effective way of handling and storing loads. Protect your product from dust and moisture, keep your cartons firmly on the pallet and your warehouse organized.

Benefits of Stretch Wrap

The biggest benefit of stretch wrap is its elastic recovery time, which ensures that you can always remain confident that your items will be tightly and securely held. This is different from shrink wrap, which shrinks over time due to heat exposure. Although this characteristic of shrink wrap provides flexibility in terms of the kinds of items it can fit over, stretch wrap is best for those that value security and reliability over flexibility.

For anyone that wants a stable and efficient storage method for their products, stretch wrap is the ideal choice. Canadian-made Toronto stretch wrap packaging sold by Danshar Polybag and Resin Inc. is solid and skin-tight. Cost effective and easy to use, it will protect any object from the elements. Our customers' time is valuable and we understand their need for quality products that are leaders in the industry.

Blowing and Casting

There are two main ways of creating stretch wrap: blowing and casting. When blowing stretch wrap, the stretch wrap resin is melted, blown and then air-cooled. Alternatively, casting utilizes cooling rollers, which the stretch wrap resin passes over. Blowing is the slower and more expensive process due to the low amount of final product that it creates per hour. Despite this downside, it provides a higher quality final product with greater strength and reliability. However, for those that want their stretch wrap quick and cheap, casting is the best option as it can produce the final product in approximately an hour for a very low cost.

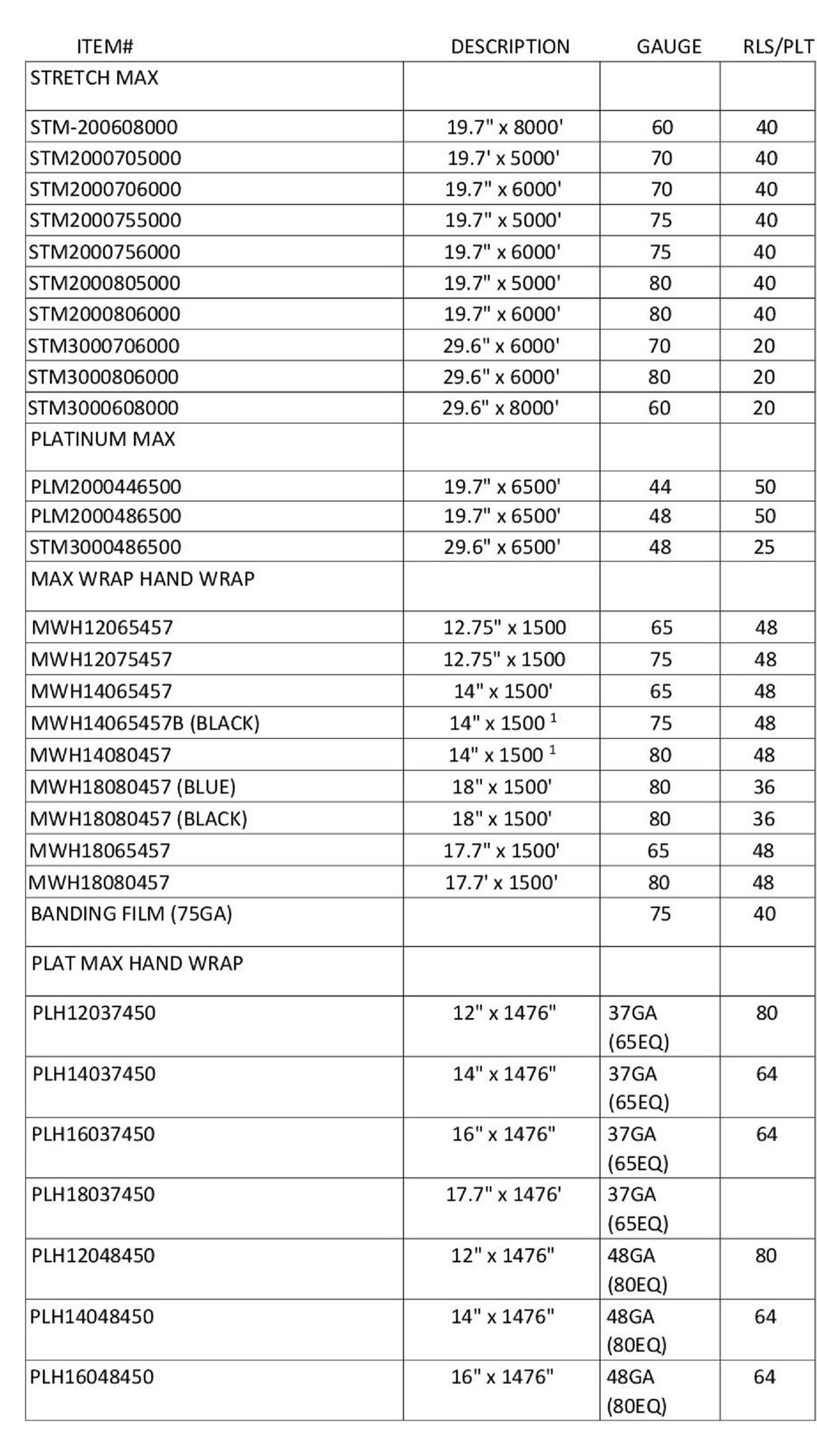

Stretch Wrap Film Gauges Available

Toronto Stretch Wrap Supplies in Stock

Ultimately, pallet stretch wrap is an effective choice for any kind of manufacturer due to the reliability and security that it offers your products. The nature of stretch wrap assures that whatever the size of the item you need to cover, you will be able to do so safely and securely, allowing you to rest easy knowing that your products are safe. Additionally, dust, moisture and other environmental contaminants are commonplace is manufacturing plants and pallet stretch wrap is a great way to keep your products safe, secure and free of contamination.

For more information, please see Toronto Stretch Wrap.

Please contact us for quotes.

2899 Steeles Ave. W.,

Units 9 & 10,

North York, Ontario

M3J 3A1

Fax: 1-855-669-6184

For skid quantities of stretch wrap, resin, or plastic bags only, please call

416-993-6804

orderdesk@torontostretchwrap.com

(Please note: We will not reply to import/export/hiring/transport or

SEO requests or to custom orders of less than 30,000 bags.)*

By appointment.