80 Gauge Stretch Wrap

One of the most highly requested stretch films on the market is 80 gauge stretch wrap. Using this gauge stretch wrap, one can easily palletize heavy loads with this high-performance film with superior cling and high load holding force. It can often be challenging for businesses to find stretch wrap that stretches and rolls efficiently. For businesses that use stretch wrap frequently, this gauge stretch wrap manufactured through the cast extrusion process is an ideal choice.

80 Gauge Stretch Wrap Features

A standard 80 gauge stretch film has different specifications depending upon how it was manufactured. Our stretch films are manufactured through the cast extrusion process. Cast differs from blown as it uses chilled rollers to cool film resin, whereas blown uses air to cool film resin. The result in both films are varied characteristics in the stretch film. Cast film has superior optics than cloudy blown film. It is also the more cost-effective option of the two, as blown film has greater puncture resistance, but is much more expensive for businesses. New resin mixtures allow cast films to be thinner and stiffer than blown film yet offer the same load retention as true 80 gauge stretch wrap.

When stretch wrap is frequently used, it is important to know what type of film is ideal for its intended application. Companies may believe they are using true 80 gauge stretch wrap only to find their goods damaged in transit. For some applications, ordering a true 80 gauge stretch wrap may be considered over gauging and cost your business more money. Therefore, companies should be familiar with the type of stretch film they use for its intended application to ensure they are receiving accurate quotes. There are other options available on the market that can be as advantageous as 80 gauge stretch wrap. Equivalent stretch wrap has been designed to be more environmentally friendly by using less petroleum in the production process, to be more cost-effective, and increase efficiency.

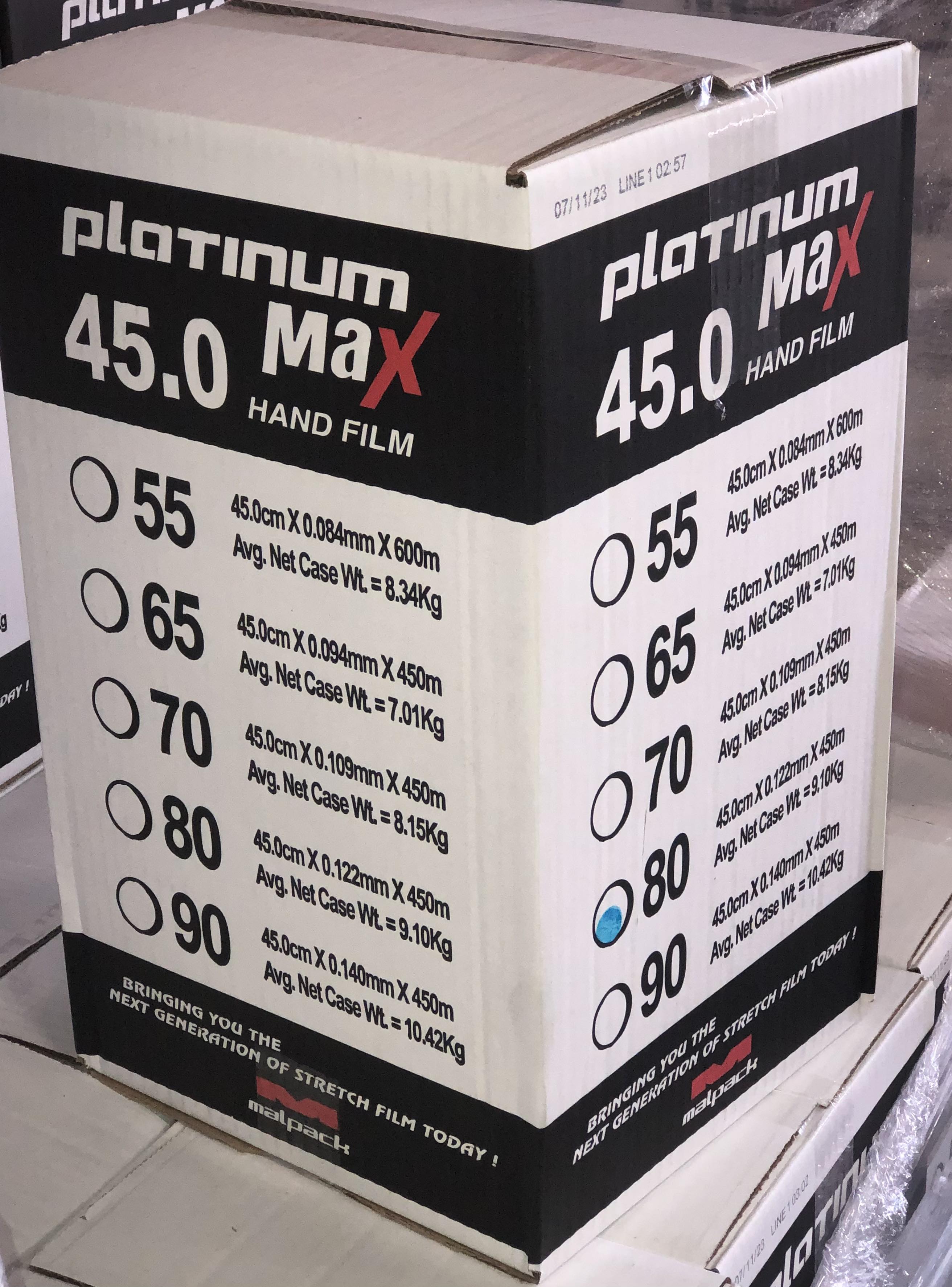

The term 80 gauge refers to the thickness of the stretch wrap. A gauge is a unit of measurement used to measure thin plastics. Stretch wrap gauging is not to be confused with wire gauging which measures the size of a wire. Other commonly used units of measurement for plastics are microns, mil, millimeters, and inches. Micron is the preferred method of measurement. Therefore, a stretch wrap that has 20-micron thickness is equivalent to 80 gauge stretch wrap. While stretch films may have the same thickness, they do not have the same film quality. The most reliable way to identify if a stretch film is a true 80 gauge stretch wrap is through use of a micrometer, which is a measuring tool used to measure thickness of objects.

Our 80 gauge stretch wrap has 200 percent stretch, allowing it to be stretched up to 200 percent its original length when applied properly. Not only does 80 gauge stretch wrap come off the roll quietly, but it also offers high puncture resistance which is excellent for heavier pallet loads. The 80 gauge stretch wrap has high clarity, which is beneficial for barcode reading, scanning, and load identification. This film with its high load holding force will keep skids tightly bound, wrapped, and secured. The quality allows for a smooth and simple release allowing workers to wrap pallet loads quickly and with minimal effort. This translates into cost savings for our customers, whose workers will be able to work faster and use much less stretch wrap to achieve superior results.

Our 80 gauge stretch wrap is not only for wrapping pallets, but it is also great for wrapping furniture. This is essential for movers and shipping companies who are seeking to bundle loads together and to shield furniture from potential damage which may occur during transportation. Our 80 gauge stretch wrap is specially manufactured to carry loads up to 2,500 lbs.

There are many factors to consider when selecting the right gauge for your stretch film application. Before choosing 80 gauge stretch wrap, consider the weight of the pallet load. The heavier the load you are seeking to wrap, the more force the stretch wrap will come under, and therefore, you will have to consider strong and durable stretch film options. Next, the shape of the load should be examined. Pallet loads have a uniform shape and require less holding power whereas irregularly shaped loads with sharp corners or edges need stronger stretch wrap.

At Danshar Polybag and Resin and Toronto Stretch Wrap, we can help you identify whether 80 gauge stretch wrap is ideal for your intended application. Our 80 gauge stretch wrap is versatile, medium-duty, and a true-gauged film. It is the most common thickness of stretch wrap. We have been in the business for over 40 years and can help you determine which stretch wrap gauge will suit the needs of your business.

Please contact us for quotes.

More Toronto Stretch Wrap Products

2899 Steeles Ave. W.,

Units 9 & 10,

North York, Ontario

M3J 3A1

Fax: 1-855-669-6184

For skid quantities of stretch wrap, resin, or plastic bags only, please call

416-993-6804

orderdesk@torontostretchwrap.com

By appointment.